+86-13812067828

+86-13812067828

When it comes to optimizing performance and longevity in agricultural equipment, selecting the right type of heat exchanger is a decision that should never be overlooked. Agricultural machinery heat exchangers perform a critical role in maintaining stable temperatures in engines, hydraulics, and other core systems, especially during long hours of operation in demanding field conditions. With various designs available—each suited to different tasks and environments—it’s worth taking a closer look at how they compare, and what makes one more suitable than another in real-world agricultural applications.

Among the most common designs, plate-type heat exchangers are appreciated for their compactness and high heat transfer efficiency. They consist of multiple thin, corrugated plates that create turbulent flow, maximizing the thermal exchange between fluids. In agricultural machinery where space is limited and maintenance access is tight, these exchangers offer a clean, modular solution. However, they are more sensitive to clogging when fluids carry particulates, which is often the case in farming environments, especially if filtration isn’t properly managed.

Shell-and-tube heat exchangers are another staple, particularly valued for their durability and ease of cleaning. Their robust construction makes them a strong candidate for heavy-duty tractors and harvesters where fluid contamination or thermal load fluctuations are more pronounced. The larger size and heavier weight might be a trade-off in more compact machinery, but for high-performance systems with a need for steady thermal regulation, they often prove a reliable choice.

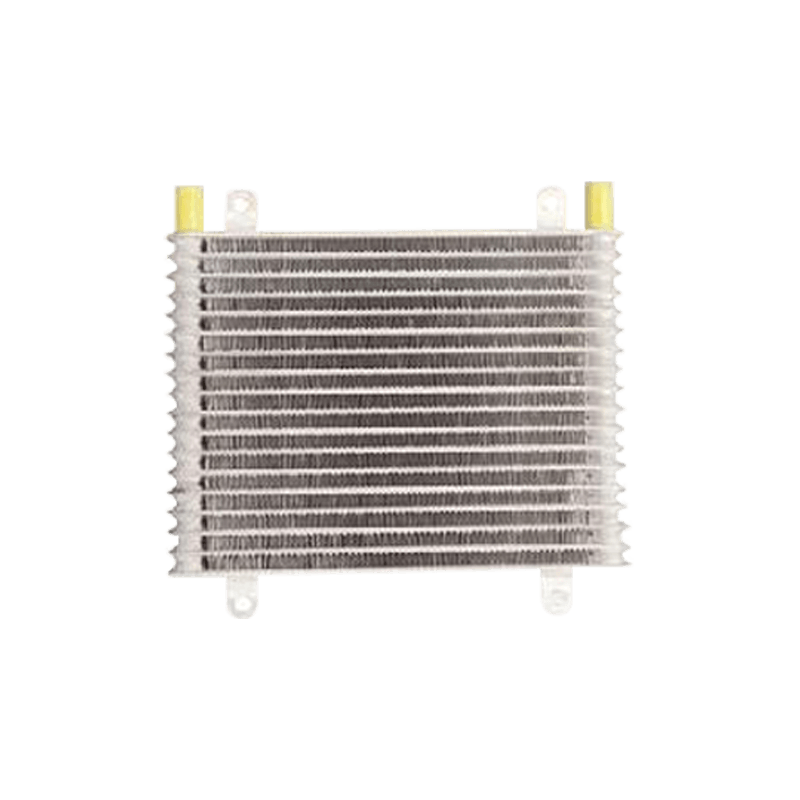

Air-cooled heat exchangers bring a different advantage to the table—they eliminate the need for a secondary coolant fluid, using ambient air to remove excess heat. This design is common in hydraulic oil cooling and auxiliary systems in irrigation equipment or sprayers that operate in remote areas. However, airflow can be easily obstructed by dust and crop debris, so careful consideration of fan strength, grille design, and mounting position is crucial to avoid performance degradation in agricultural heat exchanger applications.

Fin-and-tube exchangers represent a hybrid approach, often used in systems where both space and airflow efficiency matter. With aluminum fins wrapped around copper or steel tubes, they strike a balance between cost, heat transfer rate, and form factor. In agricultural machinery heat exchangers, this type is frequently found in radiator systems, where they can efficiently cool engine fluids while resisting corrosion when properly coated.

From a manufacturing perspective, each of these plate-type heat exchanger types must be evaluated not only for technical compatibility but also for lifecycle cost, serviceability, and resistance to environmental stressors such as vibration, mud, and variable load cycles. For instance, while plate exchangers might offer excellent efficiency, their maintenance complexity may not be ideal for every farm operator. Conversely, shell-and-tube units, though bulkier, may lower long-term maintenance risks.

For OEMs, aftermarket service providers, or equipment distributors, understanding these differences is key to specifying the best solution for their machines or clients. As a manufacturer with years of experience in agricultural thermal systems, we emphasize a tailored approach—matching exchanger design to the working realities of the farm environment. Whether the goal is maximizing uptime, reducing energy loss, or simply extending the lifespan of your equipment, choosing the right heat exchanger can make a significant difference.

Ultimately, while all agricultural machinery heat exchangers serve the same core purpose—removing unwanted heat—their differences in design, application, and performance are far from trivial. Taking the time to compare them through the lens of actual agricultural use cases ensures that your machines stay efficient, reliable, and ready for every season.