+86-13812067828

+86-13812067828

In the world of agricultural machinery, heat management is a critical issue. Whether it’s a tractor, combine harvester, or irrigation system, equipment works under tough conditions that put significant strain on internal systems. The efficient operation of these machines depends heavily on the performance of agricultural machinery heat exchangers, which are designed to regulate temperatures, prevent overheating, and ensure machinery runs smoothly for extended periods. However, as farming demands increase, so do the thermal challenges these machines face, making heat exchanger efficiency more important than ever before.

Agricultural machinery operates in extreme environments where the combination of high mechanical loads, fluctuating weather conditions, and prolonged hours of work can lead to overheating. Tractors and combines, for example, often work for hours at a stretch under full load, which significantly raises the temperature of the engine coolant, hydraulic fluids, and other systems. If these fluids overheat, it can lead to engine failures, fluid degradation, and overall poor performance. This is where high-quality agricultural machinery heat exchangers come into play, offering a solution that not only prevents damage but also enhances performance and extends machinery lifespan.

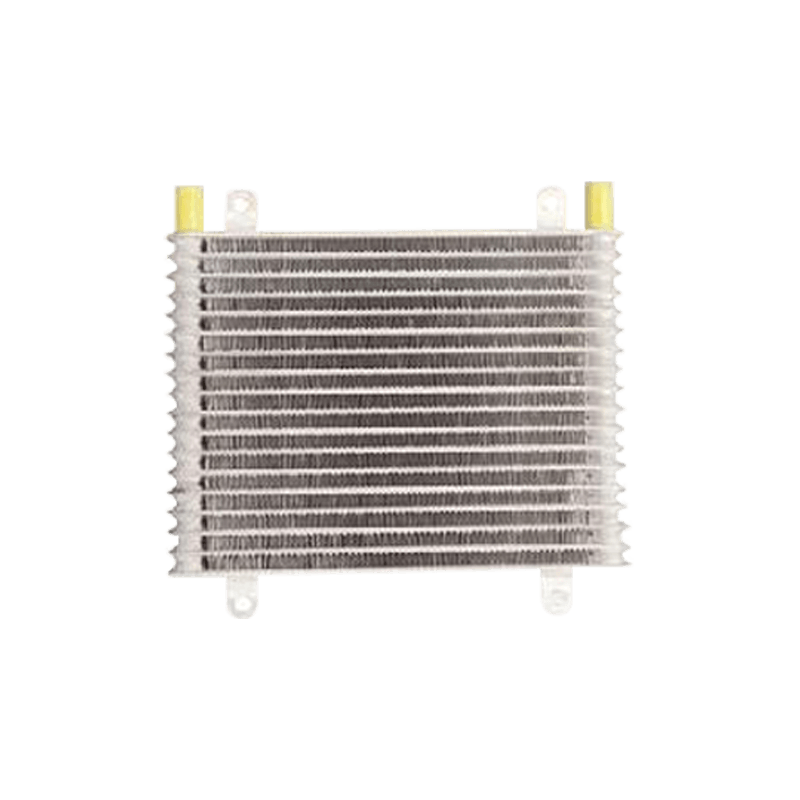

The heart of any heat exchanger lies in its ability to effectively dissipate excess heat. For agricultural equipment, heat exchangers must be designed with special consideration for environmental factors. Dust, moisture, and exposure to high-vibration conditions all play a role in determining the durability and efficiency of a heat exchanger. In the field, heat exchangers must stand up to these elements while maintaining consistent thermal performance. This means using materials such as aluminum, copper, and stainless steel, known for their excellent heat transfer properties and resistance to corrosion, to ensure longevity and reliability in harsh agricultural environments.

Moreover, these heat exchangers must be able to adapt to the varying temperature loads that come with different tasks. Whether it’s the continuous operation of irrigation pumps or the high-torque work of tilling, each machine has its own specific cooling needs. To meet these needs, agricultural machinery heat exchangers are often custom-designed or modular to fit the precise specifications of the equipment. By optimizing the surface area, fin type, and flow patterns, these exchangers can increase cooling efficiency while keeping the overall design compact and lightweight, which is critical for machinery that needs to operate in tight spaces.

While the primary function of heat exchangers is to maintain temperature stability, their design must also account for fuel efficiency and overall system reliability. Overheating not only reduces fuel efficiency by causing engines to operate less effectively but can also increase emissions, which are becoming a growing concern for sustainable farming. A well-designed agricultural machinery heat exchanger helps maintain optimal engine temperature, ensuring combustion is as efficient as possible and reducing fuel consumption. This leads to both cost savings for farmers and a smaller environmental footprint, making it an essential component for modern farming operations.

Additionally, maintaining the efficiency of these heat exchangers is paramount to ensuring that agricultural machinery continues to perform at its best. Regular cleaning and inspection are necessary to avoid the buildup of dirt, debris, and corrosion that could compromise the heat exchanger’s performance. Without proper care, even the most robust agricultural machinery heat exchangers can begin to fail, leading to overheating issues that affect overall equipment efficiency. Fortunately, the materials used in these exchangers—like stainless steel and copper—are designed to withstand corrosion and ensure long-term durability with minimal maintenance.

As farming technology continues to evolve, the future of agricultural machinery heat exchangers looks promising. Innovations in materials and design are making these components even more efficient and durable, allowing for better performance under the toughest conditions. From smart sensors that monitor temperature in real-time to new, lightweight materials that provide even better heat dissipation, the next generation of agricultural heat exchangers will be even more tailored to the unique needs of modern farming equipment. By staying ahead of these trends, manufacturers can ensure their equipment meets the increasing demands of the agricultural industry, providing farmers with tools that keep their operations running smoothly and efficiently.