+86-13812067828

+86-13812067828

Plate fin heat exchangers are known for their efficiency in transferring heat between fluids, but when it comes to handling multiphase flow systems, they face unique challenges. Multiphase flows, where gas, liquid, or even solid phases coexist within a fluid system, can complicate the heat exchange process. However, the adaptability of plate fin heat exchangers makes them a powerful solution for these demanding applications, especially when thermal performance, space efficiency, and pressure control are critical.

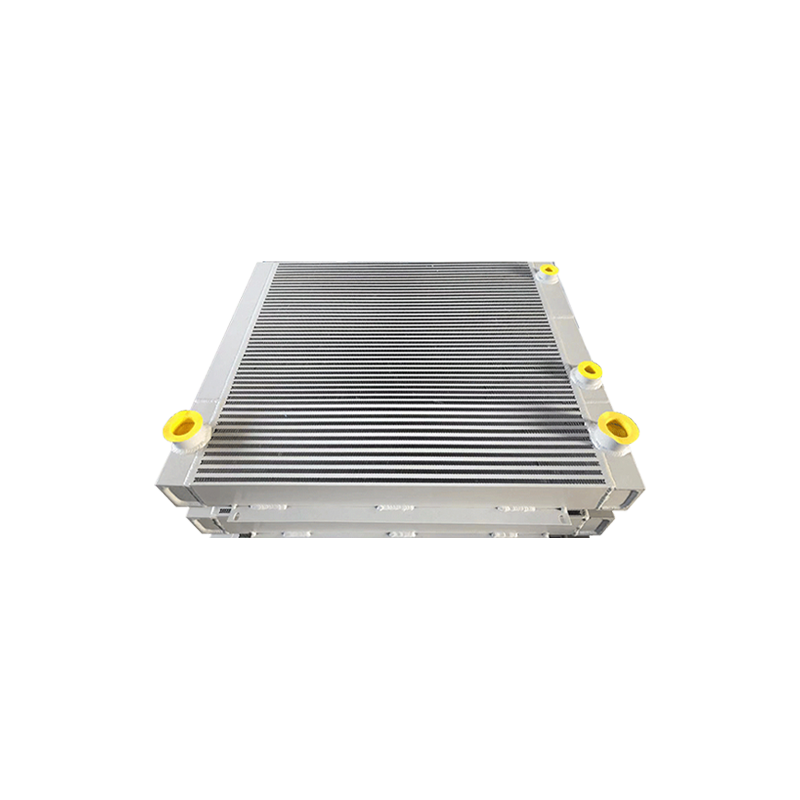

The fundamental design of a plate fin heat exchanger allows for fluid flow through carefully arranged channels created by thin, corrugated fins. In typical single-phase flow systems, this design efficiently maximizes heat transfer by increasing the surface area while minimizing pressure drop. But when you introduce a multiphase flow—such as in refrigeration cycles, chemical reactors, or gas-liquid separation systems—additional factors come into play. The different phases in the flow, often moving at varying velocities, can lead to non-uniform heat distribution, making it essential for the exchanger to be designed with this variability in mind.

To overcome these challenges, engineers often tweak the standard design of plate fin heat exchangers. This can involve altering the fin arrangement, using advanced materials, or optimizing the number of channels to better handle the varying flow characteristics. For instance, offset strip fins are commonly employed in these systems as they help reduce flow maldistribution, ensuring that the heat exchanger delivers consistent performance despite the fluctuations in flow rates and phase changes. The right design not only improves heat transfer but also minimizes the risk of fouling or clogging, which is a significant concern in multiphase flow systems.

Another critical consideration in multiphase applications is pressure drop. Plate fin heat exchangers, when correctly designed, can handle multiphase fluids without significant losses in pressure. This is especially important in applications like petrochemical refining, where maintaining pressure is essential for system efficiency. The design of the fins and flow channels is key here—carefully tailored fin configurations can reduce flow resistance while maintaining the necessary heat exchange efficiency. Optimizing this balance between heat transfer and pressure drop is where the expertise of manufacturers like us comes into play, ensuring the highest performance in demanding conditions.

The materials used in plate fin heat exchangers also play a crucial role when dealing with multiphase flows. For example, when working with corrosive or high-temperature fluids, the choice of materials such as stainless steel or titanium becomes essential. These materials offer resistance to corrosion and high mechanical strength, making them ideal for multiphase applications where fluids may contain aggressive chemicals or experience extreme temperatures. By using these advanced materials, plate fin heat exchangers can ensure long-term reliability and sustained performance in challenging environments.

Moreover, the integration of multiphase heat exchangers into complex systems requires a deeper understanding of fluid dynamics. In some industries, such as power generation or aerospace, the need to manage complex fluid systems while optimizing heat transfer efficiency is vital. For these applications, plate fin heat exchangers must be designed with careful attention to the specific fluid properties, flow rates, and thermal demands. Manufacturers must offer custom solutions that ensure that the exchangers are not only efficient but also capable of withstanding the intense operational conditions present in these sectors.

When multiphase flow conditions are encountered, precision in design becomes more important than ever. In some cases, additional features such as enhanced surface coatings or internal baffling are introduced to facilitate better fluid distribution and heat transfer. This kind of customization makes plate fin heat exchangers versatile and adaptable to a wide range of industrial requirements, ensuring that they meet the specific needs of each client, whether it’s a gas-liquid separation process or a multi-stream heat recovery system.

Ultimately, the ability of plate fin heat exchangers to manage multiphase flow applications highlights their exceptional versatility and performance. As industries evolve and the demand for more energy-efficient, space-saving thermal management solutions grows, these heat exchangers stand out as a reliable choice. By providing a compact, effective solution that balances heat transfer efficiency, pressure control, and material durability, manufacturers can offer a product that meets the most stringent industrial demands. For clients looking to optimize their thermal systems, plate fin heat exchangers provide an advanced, reliable, and cost-effective solution that can enhance both performance and sustainability.