+86-13812067828

+86-13812067828

Effective thermal management plays a vital role in ensuring the longevity and performance of modern powertrains, especially as vehicle systems become more complex and operate under increasingly demanding conditions. Whether in traditional internal combustion engines or advanced electric drivetrains, powertrain heat exchangers are at the heart of this process. These components work continuously to dissipate excess heat, preventing overheating that could otherwise lead to mechanical stress, component degradation, and reduced operational efficiency. By maintaining optimal temperature ranges, they directly contribute to the durability of critical parts such as engines, transmissions, and hybrid modules.

In high-performance or heavy-duty applications, the thermal load on powertrain systems can be immense. Without proper cooling mechanisms, metal fatigue, lubricant breakdown, and material warping become real risks. This is where well-engineered powertrain heat exchangers come into play. Designed with precision and built using high-grade materials, these systems ensure consistent heat dissipation even under extreme operating conditions. Their ability to maintain stable temperatures not only prevents sudden failures but also slows down long-term wear, extending service intervals and reducing maintenance costs.

One often overlooked aspect of thermal management is its impact on system efficiency. Overheated components tend to perform inefficiently—engines may run richer to compensate for heat, transmissions might shift sluggishly, and electric motors can throttle output to protect themselves. By integrating robust powertrain heat exchangers , manufacturers can ensure that each part operates within its designed thermal window. This results in smoother performance, better fuel economy, and lower emissions, all while safeguarding the system from avoidable strain.

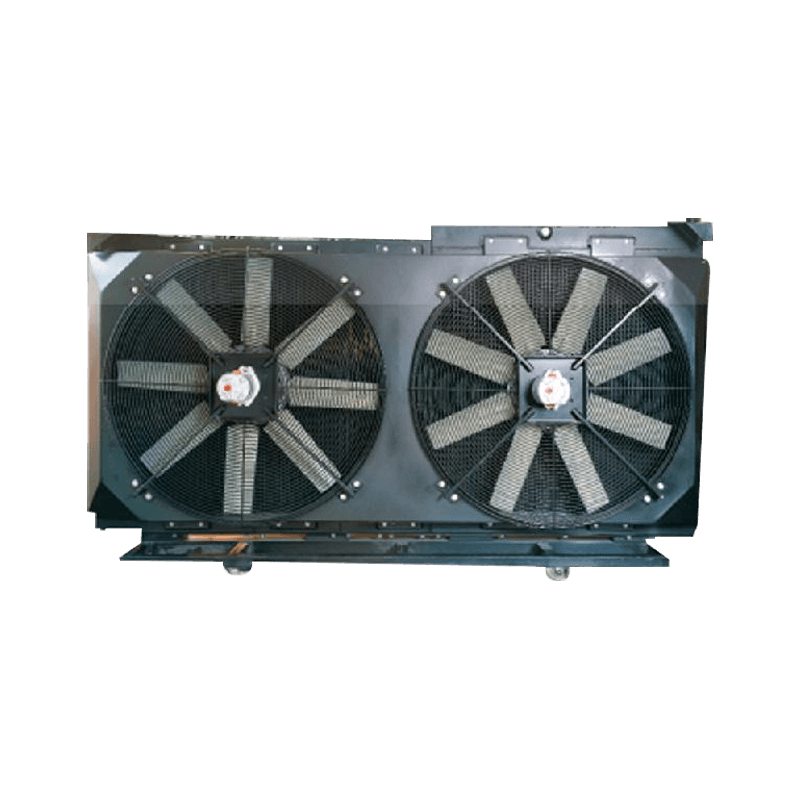

From a design perspective, modern powertrain heat exchangers must balance multiple engineering priorities. They need to be compact enough to fit within constrained engine bays, yet powerful enough to handle increasing thermal loads. Innovations such as microchannel technology, enhanced fin structures, and optimized flow paths have significantly improved their effectiveness. Manufacturers who understand these dynamics can offer tailored solutions that align with specific vehicle platforms, whether it’s for commercial fleets, off-road machinery, or next-generation EVs.

For businesses sourcing thermal management solutions, selecting the right powertrain heat exchangers is more than just a technical decision—it's a strategic investment in reliability and performance. As original equipment manufacturers (OEMs) and Tier 1 suppliers continue to push the boundaries of power density and efficiency, the importance of a reliable cooling partner becomes evident. Collaborating with experienced producers ensures access to tested designs, proven performance data, and scalable manufacturing capabilities tailored to evolving industry standards.

Moreover, the integration of smart monitoring features into modern powertrain heat exchangers allows for predictive maintenance and real-time thermal control. With sensors embedded in coolant loops and oil circuits, today’s systems can alert operators to abnormal temperature spikes before they escalate into serious issues. This level of intelligence not only enhances safety and uptime but also provides valuable insights for fleet managers and service technicians looking to optimize maintenance schedules.

As thermal challenges evolve across different types of vehicles, so too must the technologies that address them. Whether you're designing for conventional ICEs, hybrid systems, or fully electric drivetrains, partnering with a manufacturer that understands the lifecycle implications of thermal stress is essential. Our team brings years of experience in developing powertrain heat exchangers that deliver both performance and durability, helping our clients build smarter, cooler, and more resilient machines for the global market.