+86-13812067828

+86-13812067828

Automotive mechanical heat exchangers are integral components that ensure the smooth functioning of a vehicle's complex systems. These devices, designed to transfer heat between two or more fluids, play a vital role in managing the temperatures of crucial automotive systems, thus boosting overall vehicle performance and comfort. From engine cooling to air conditioning and exhaust gas recirculation (EGR) systems, various types of heat exchangers are tailored for specific tasks. Radiators, intercoolers, condensers, and oil coolers are the most common varieties, each fulfilling distinct functions that contribute to the efficiency of modern vehicles.

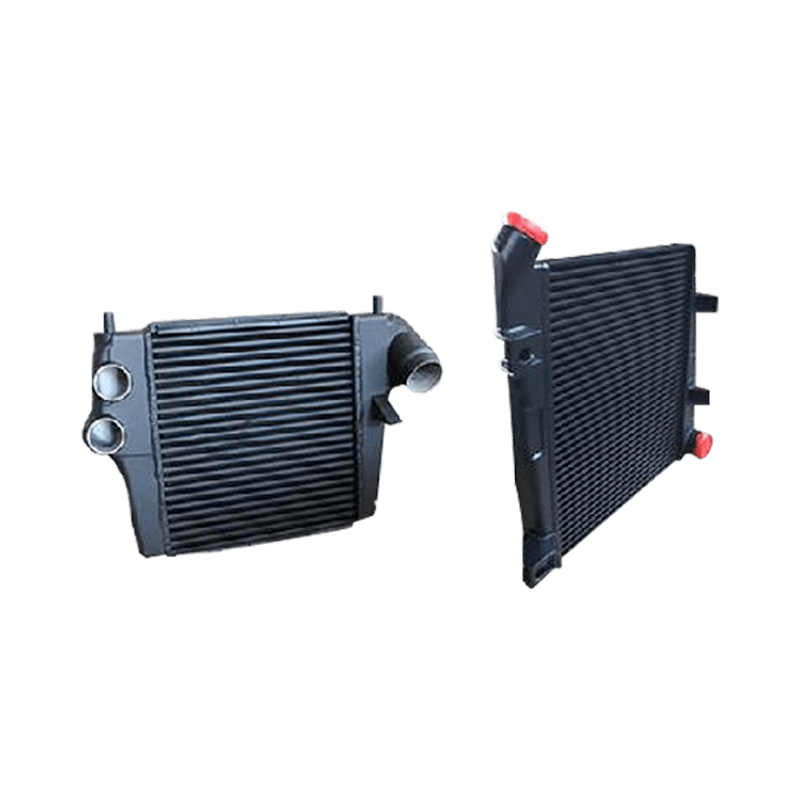

At the core of many automotive systems, the radiator serves the primary purpose of cooling the engine coolant, preventing the engine from overheating during operation. As the engine generates a significant amount of heat, the radiator absorbs excess heat from the coolant and dissipates it into the surrounding air, ensuring that the engine maintains an optimal temperature for peak performance. Similarly, intercoolers, which are crucial for turbocharged engines, help cool the compressed air before it enters the engine. By lowering the temperature of the intake air, intercoolers not only enhance fuel efficiency but also prevent engine knock, promoting smoother operation.

Condensers, typically found in air conditioning systems, work by releasing heat from the refrigerant gas, converting it into a liquid. This process is essential for maintaining a cool cabin environment, especially during hot weather. The condenser's efficiency directly impacts the effectiveness of the A/C system, ensuring that passengers stay comfortable while also preserving the vehicle’s overall energy efficiency. Meanwhile, oil coolers are designed to maintain the temperature of engine oil at an optimal level, preventing the oil from overheating, which could lead to engine damage. By transferring excess heat away from the oil, these coolers ensure smoother engine operation, longer engine life, and better fuel efficiency.

The design and material selection of automotive heat exchangers are crucial in achieving high thermal efficiency and durability. Aluminum and copper are the go-to materials for their excellent thermal conductivity and lightweight properties, making them ideal for automotive mechanical heat exchangers. As vehicles evolve, manufacturers are increasingly turning to advanced materials and designs to meet the growing demands for fuel efficiency and performance. This is particularly true for electric and hybrid vehicles, where battery cooling has become a new frontier for heat exchanger technology. By managing the temperature of high-voltage batteries, heat exchangers help maximize battery life, prevent overheating, and improve safety.

With continuous advancements in automotive engineering, the importance of efficient heat exchangers cannot be overstated. These components are no longer just about cooling; they’re about enhancing the vehicle's overall performance, from engine longevity to climate control. As more complex systems emerge, manufacturers are continuously innovating to ensure that automotive heat exchangers not only meet but exceed industry standards, ensuring a seamless driving experience for consumers worldwide. If you’re looking to optimize the thermal management of your vehicle’s systems, investing in high-quality automotive heat exchangers is a crucial step toward better efficiency and performance