Product Knowledge

Compact and Cost-Effective: The Advantages of Air-Cooled Plate-Fin Heat Exchangers

Among the most effective solutions for heat transfer in such environments are air-cooled plate-fin heat exchangers, which provide an outstanding balance of efficiency, compactness, and cost-effectiveness. These heat exchangers use air as the cooling medium, eliminating the need for water and offering versatile solutions for a range of industries, from oil and gas to HVAC systems.

What is an Air-Cooled Plate-Fin Heat Exchanger?

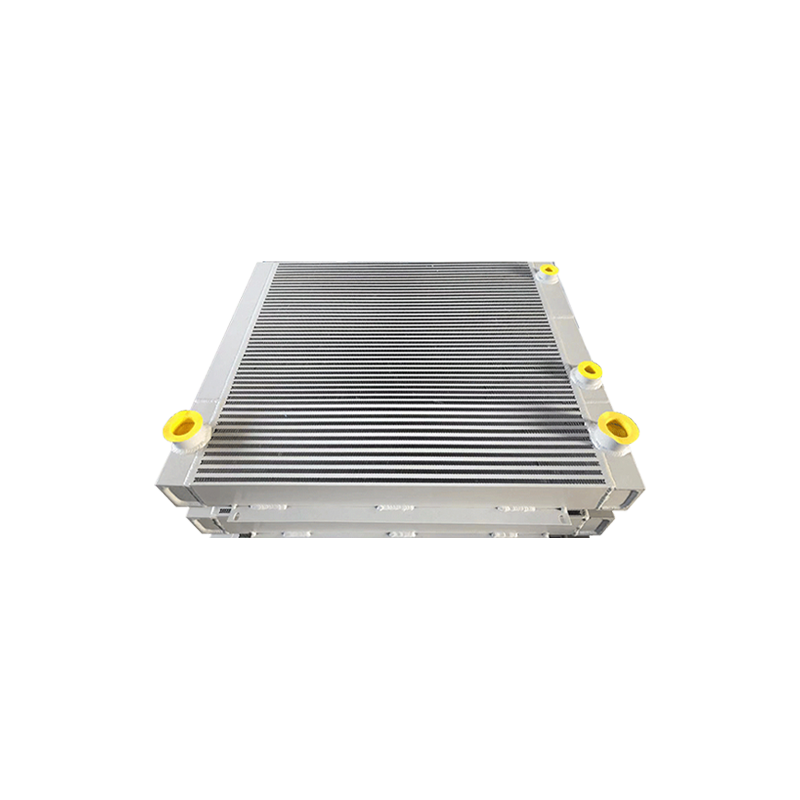

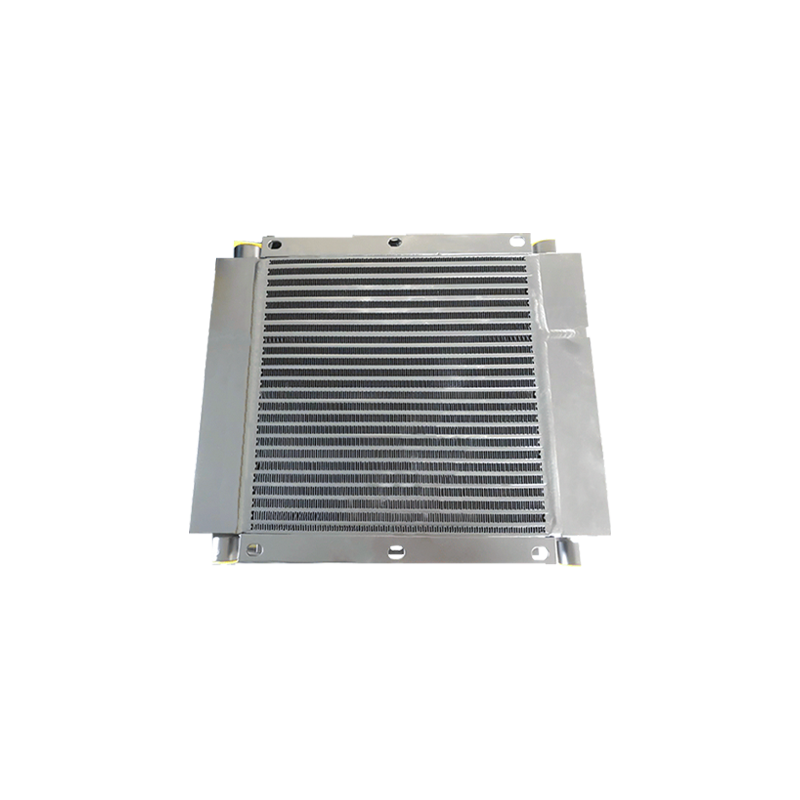

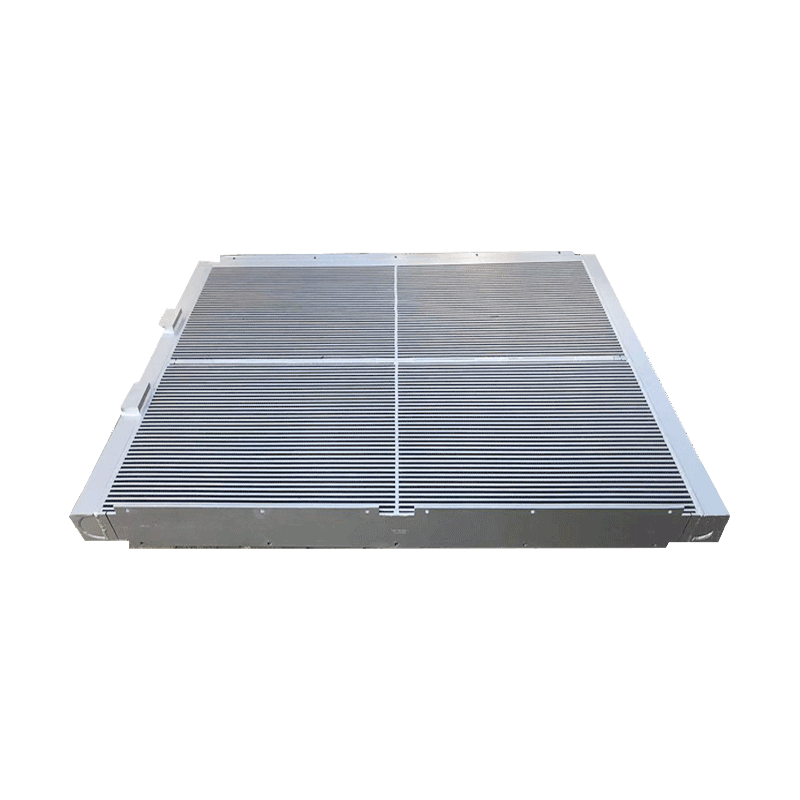

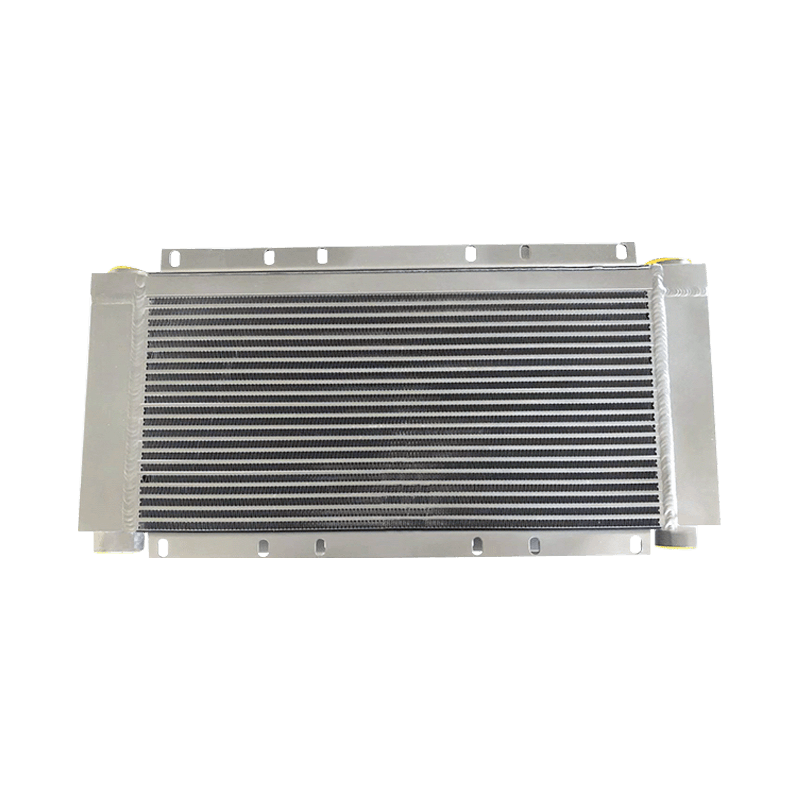

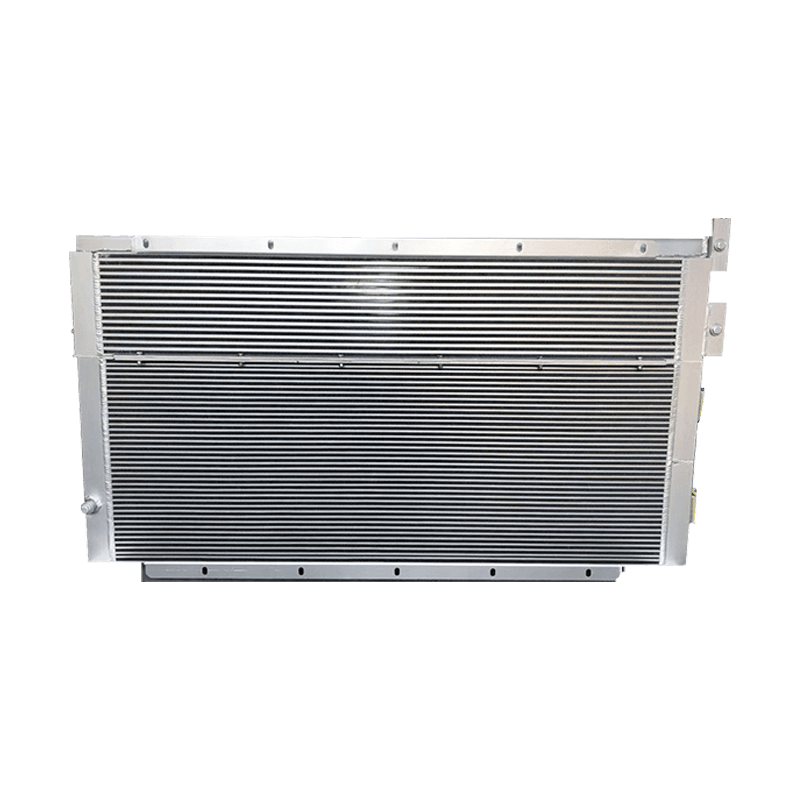

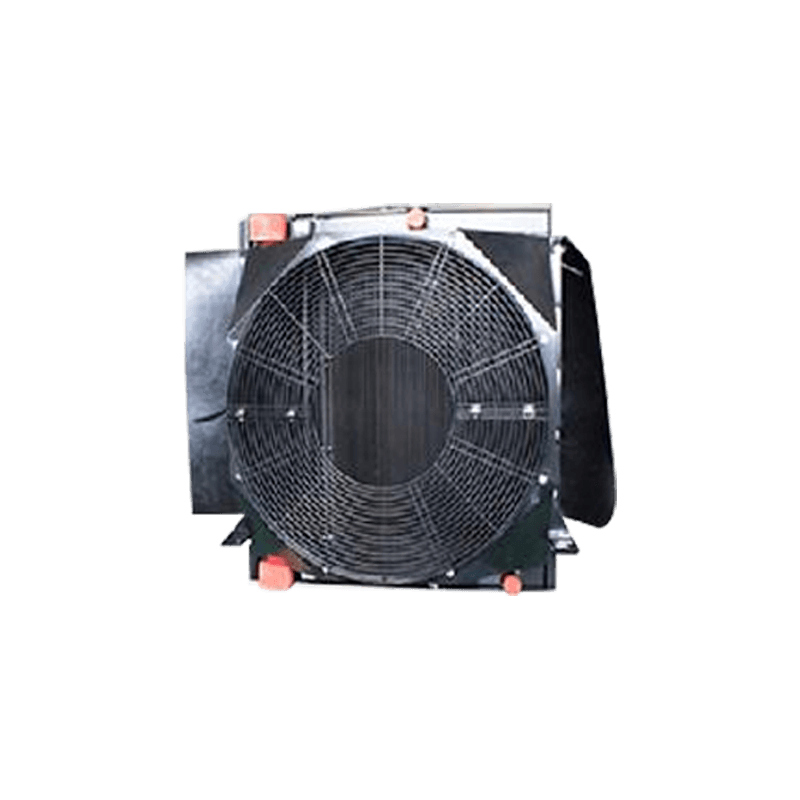

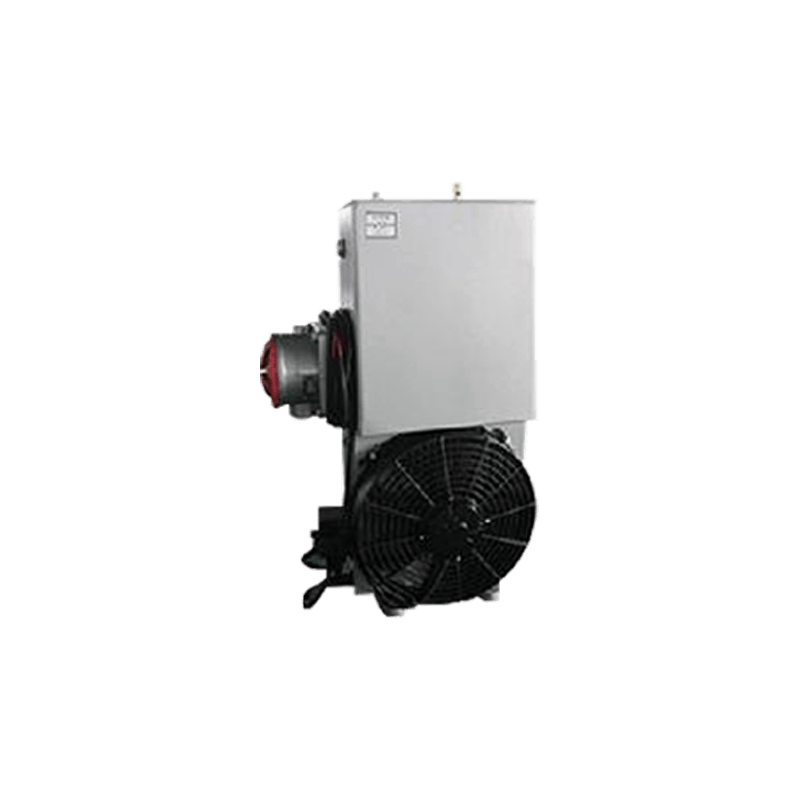

An air-cooled plate-fin heat exchanger is a compact and highly efficient thermal management device designed to transfer heat between two fluids using air as the cooling medium. Unlike traditional water-cooled systems, air-cooled heat exchangers rely on ambient air to dissipate the heat from high-temperature fluids or gases. The structure of these exchangers consists of multiple stacked plates with finned structures that enhance surface area for maximum heat dissipation, ensuring optimal thermal performance.

Made from high-conductivity materials such as aluminum or stainless steel, air-cooled plate-fin heat exchangers offer superior heat transfer efficiency. Their compact design makes them a preferred choice for industries where space is limited, as they require much less room compared to conventional shell-and-tube heat exchangers.

Benefits of Air-Cooled Plate-Fin Heat Exchangers

The primary advantage of air-cooled plate-fin heat exchangers lies in their ability to operate effectively without the need for water. In regions or industries where water usage is limited or unavailable, these heat exchangers provide a reliable and efficient solution for cooling processes. This feature is particularly valuable in sectors like petrochemicals, oil and gas, and power generation, where cooling of high-temperature fluids and gases is a constant need.

Another significant benefit is the reduction in the overall footprint. Unlike traditional heat exchangers, which can be bulky and require extensive installation space, air-cooled plate-fin heat exchangers are designed to be much more compact. This makes them ideal for applications where space constraints are a concern, such as in offshore rigs, industrial plants, or confined manufacturing environments.

Moreover, air-cooled plate-fin heat exchangers are incredibly energy-efficient. The design minimizes air pressure drop, ensuring that less energy is required to push the air through the system. This results in lower operational costs and reduced energy consumption compared to older cooling technologies. Additionally, their low maintenance requirements further enhance their cost-effectiveness.

Applications of Air-Cooled Exchangers

Air-cooled plate-fin heat exchangers are widely used in various industries. For example, in the oil and gas sector, they are used to cool high-temperature gases and fluids from compressors and other equipment. Similarly, in the petrochemical industry, these heat exchangers play a critical role in maintaining the temperature of fluids used in chemical processing and refining.

In HVAC systems, air coolers with plate-fin heat exchanger technology are utilized to efficiently manage the temperature of air circulating in large commercial and industrial buildings. Their ability to provide cooling without the need for water makes them particularly suited for areas with water scarcity or where water conservation is a priority.

Moreover, these heat exchangers are commonly found in new energy applications such as wind power generation and gas separation systems, where they effectively manage heat from energy-producing equipment. The versatility of air-cooled plate-fin heat exchangers makes them an ideal solution for a wide range of industries that require reliable, efficient, and sustainable thermal management systems.

Wuxi Jinlianshun Aluminum Co., Ltd.: Leading the Way in Air-Cooled Plate-Fin Heat Exchanger Technology

Wuxi Jinlianshun Aluminum Co., Ltd., located in Wuxi City, China, is a leading manufacturer of air-cooled plate-fin heat exchangers. The company specializes in producing aluminum plate-fin heat exchangers, which are known for their high heat exchange efficiency, lightweight design, and strong applicability. These heat exchangers are used in a variety of fields, including compressors, construction machinery, refrigeration equipment, gas separation, wind power generation, and more.

The company’s advanced manufacturing capabilities ensure that each air-cooled heat exchanger is built to the highest standards, providing exceptional performance and durability. Wuxi Jinlianshun Aluminum Co., Ltd. uses high-quality aluminum materials, which are known for their excellent thermal conductivity, to manufacture its heat exchangers. This commitment to quality ensures that their air-cooled plate-fin heat exchangers can meet the diverse needs of their customers across various industries.

Why Choose Air-Cooled Plate-Fin Heat Exchangers?

Choosing air-cooled plate-fin heat exchangers from reputable manufacturers like Wuxi Jinlianshun Aluminum Co., Ltd. offers several benefits. These heat exchangers not only reduce the need for water but also provide an energy-efficient and cost-effective solution for cooling systems. The compact design ensures that they can be easily integrated into existing systems, while their robust construction guarantees long-lasting performance with minimal maintenance.

With the increasing demand for sustainable and efficient cooling solutions, air-cooled plate-fin heat exchangers are becoming an essential component in industrial applications worldwide. Their ability to deliver high heat exchange efficiency in a compact form makes them ideal for companies looking to optimize their thermal management processes while keeping costs low.

Air-cooled plate-fin heat exchangers are transforming the way industries manage heat transfer. With their compact design, cost-effective operation, and reliable performance, they are becoming the preferred choice for various sectors that require efficient cooling solutions. Whether you’re in the oil and gas, petrochemical, HVAC, or power generation industry, the advantages of air-cooled plate-fin heat exchangers are clear. Companies like Wuxi Jinlianshun Aluminum Co., Ltd. are at the forefront of this technological advancement, offering high-quality products that meet the growing demand for efficient, sustainable thermal management solutions.

English

English русский

русский