Product Knowledge

Reducing Energy Consumption with Aluminum Plate-Fin Coolers in Industrial Machinery

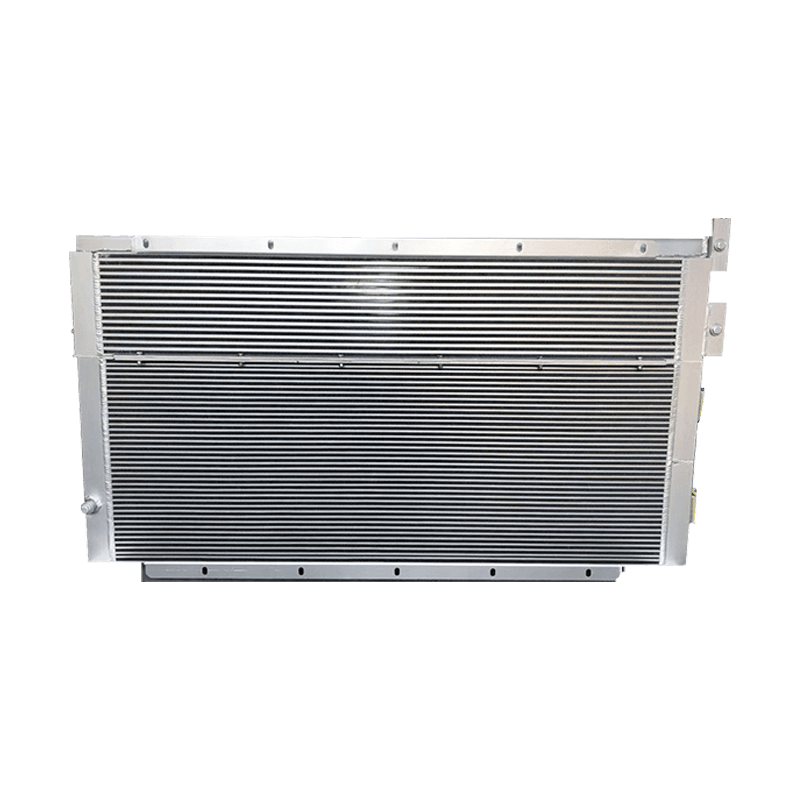

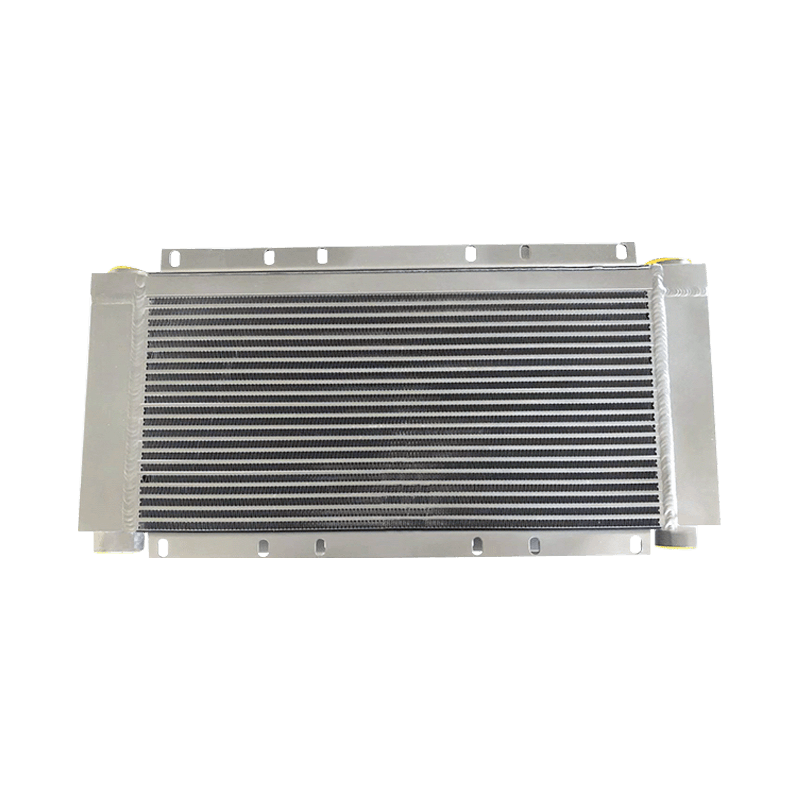

As industries strive to minimize energy costs and improve operational efficiency, adopting cutting-edge heat exchange technologies has become essential. Aluminum Plate-fin Coolers, known for their compact design and high thermal efficiency, have emerged as a critical component in optimizing energy use across various industrial sectors. These coolers, designed to maximize heat transfer while minimizing energy consumption, are revolutionizing cooling solutions in industrial machinery.

Optimized Heat Transfer with Aluminum Plate-Fin Design

The Aluminum Plate-fin Cooler is engineered to enhance the efficiency of thermal management systems, making it particularly advantageous in industrial machinery applications. Its unique plate-fin structure increases the surface area for heat exchange, improving the cooler's overall performance. This efficient heat transfer reduces the need for excessive cooling power, leading to a decrease in energy demand.

In machinery and industrial systems, overheating can cause performance degradation, unnecessary energy consumption, and potential damage. By employing the Aluminum Plate-fin Cooler, industries can achieve effective heat dissipation, ensuring that machinery operates within optimal temperature ranges with significantly lower energy input. The design's lightweight and compact nature further reduce the overall load on the cooling system, offering superior efficiency in space-constrained environments.

Enhancing Performance and Energy Efficiency

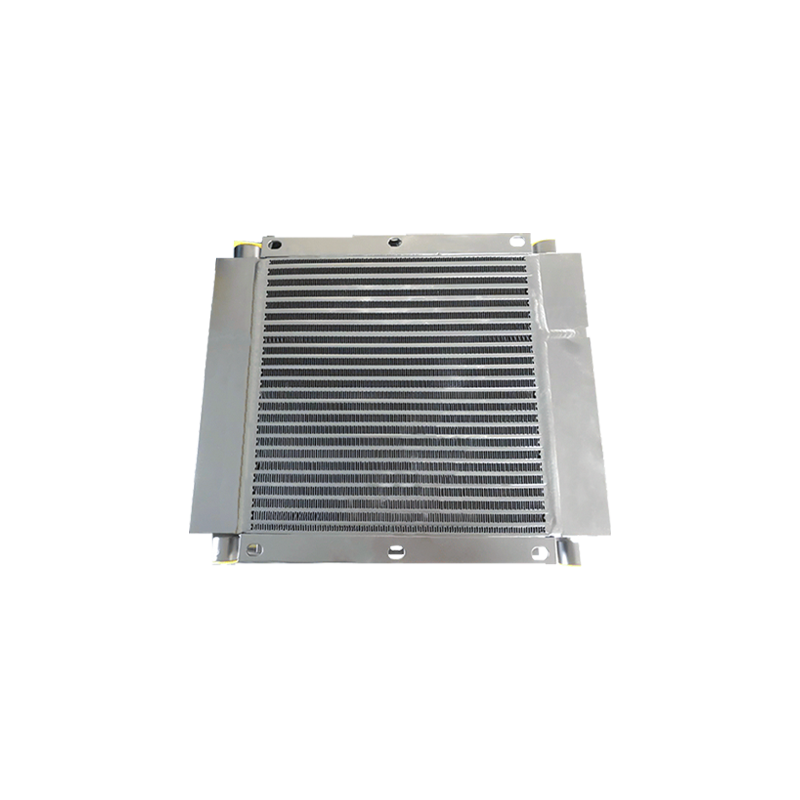

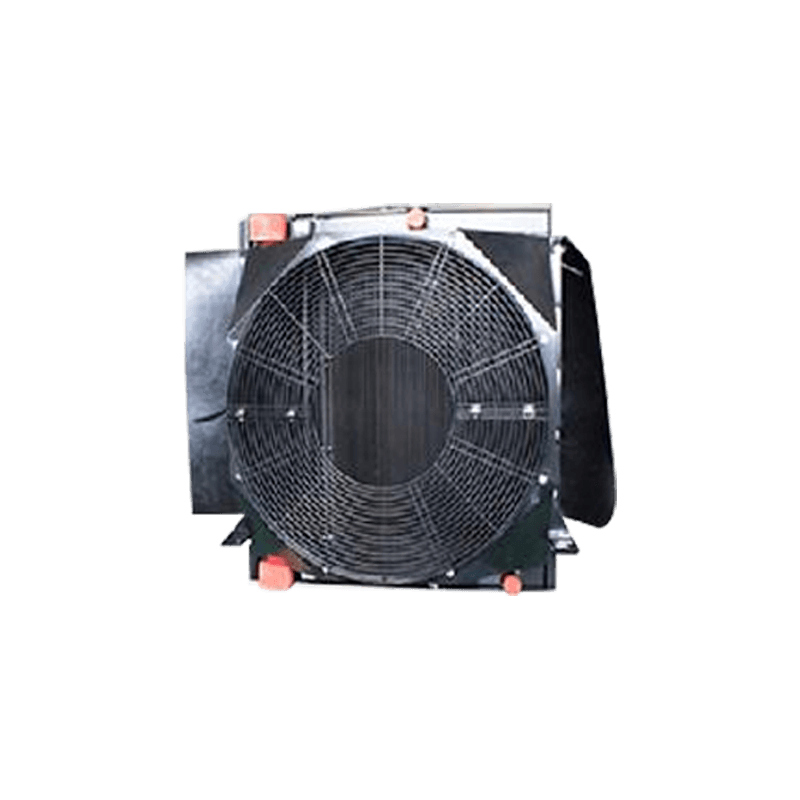

Incorporating Aluminum Plate-fin Coolers into industrial machinery is a proactive approach to reducing energy consumption. The coolers are designed to efficiently transfer heat with minimal energy expenditure. By maintaining optimal operating temperatures, they prevent the need for auxiliary cooling systems, which often require additional energy. This results in a direct reduction in operational energy costs.

The enhanced efficiency of the Aluminum Plate-fin Cooler also contributes to better system performance. By preventing thermal stress on components, these coolers ensure that machines run at peak efficiency, which not only extends their lifespan but also reduces the frequency of maintenance and repairs—further lowering energy use over time.

Durability and Long-Term Operational Savings

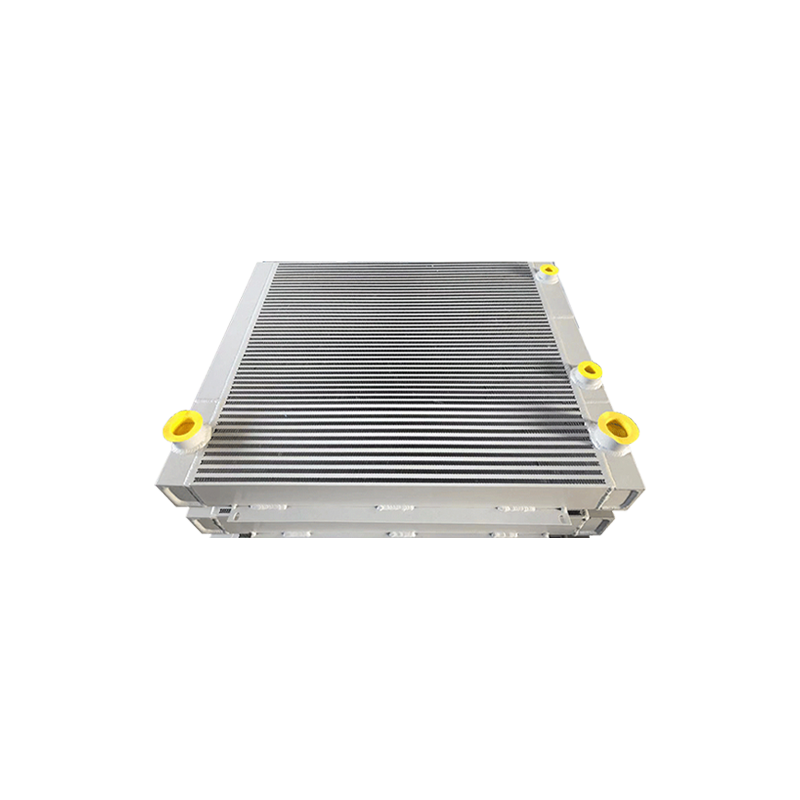

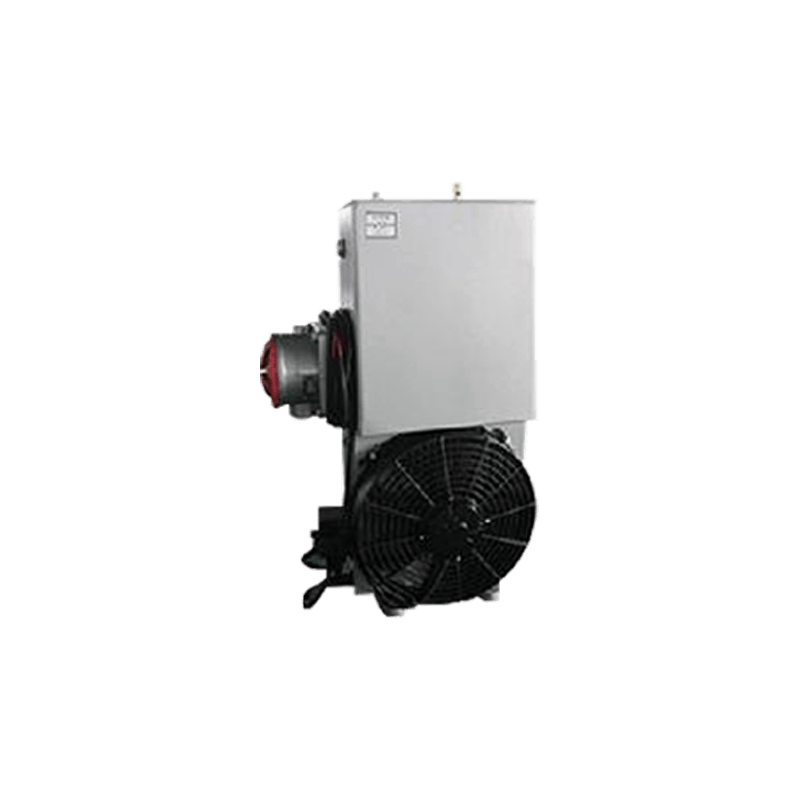

One of the standout features of the Aluminum Plate-fin Cooler is its durability. Constructed from corrosion-resistant aluminum, these coolers withstand extreme environments such as high humidity, saltwater exposure, and temperature fluctuations. This robust construction minimizes the need for frequent replacements, which can often result in downtime and energy inefficiencies.

With reduced maintenance requirements and a longer operational lifespan, the Aluminum Plate-fin Cooler helps mitigate the hidden energy costs associated with repairs or replacements. This translates into long-term savings in energy and maintenance, making it a sound investment for industries looking to improve their bottom line and reduce their environmental footprint.

Wuxi Jinlianshun Aluminum Co., Ltd.: Pioneering Energy-Efficient Cooling Solutions

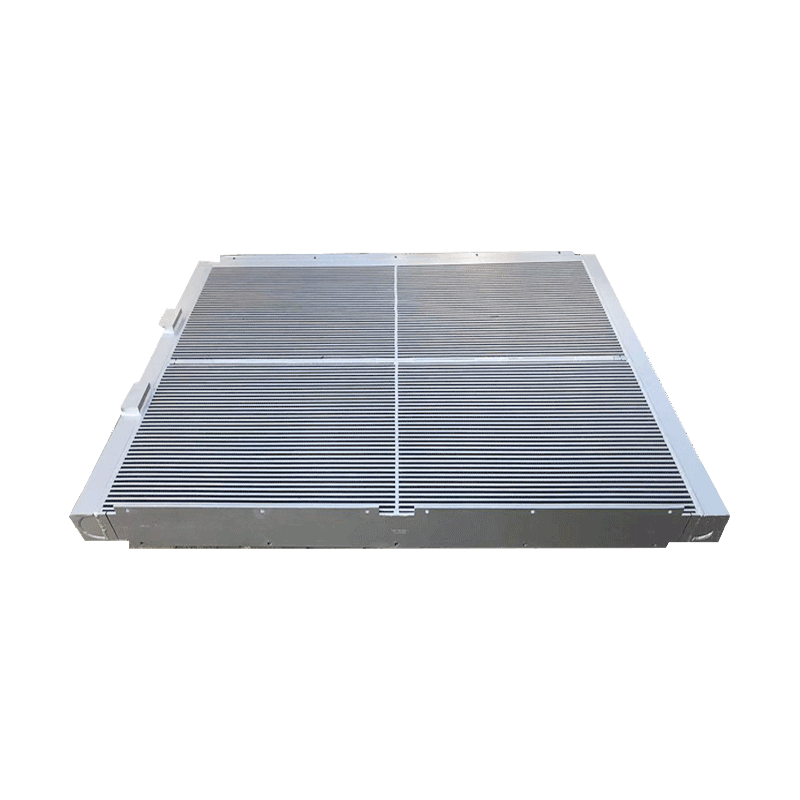

Wuxi Jinlianshun Aluminum Co., Ltd., based in Wuxi City, specializes in the manufacturing of high-performance Aluminum Plate-fin Coolers. With a focus on thermal management solutions for industries ranging from compressors to wind power generation, we deliver innovative cooling products designed to meet the specific demands of each sector.

Our coolers are engineered to achieve superior heat exchange while reducing energy consumption across various applications. Whether for construction machinery, refrigeration systems, or new energy sectors, our products offer significant energy savings and operational efficiency improvements.

Tailored Cooling Solutions for Maximum Efficiency

We understand that every industrial application requires a specific cooling solution. As a result, we offer customizable Aluminum Plate-fin Coolers that can be tailored to meet precise thermal output, pressure, and flow rate requirements. By collaborating with our clients, we ensure that each cooler is optimized for maximum performance and energy efficiency.

With our expertise in high-quality aluminum heat exchangers, we help businesses achieve lower energy consumption without compromising on cooling effectiveness. Whether you are upgrading an existing system or designing a new one, our Aluminum Plate-fin Coolers provide the ideal balance of efficiency, durability, and cost savings.

The integration of Aluminum Plate-fin Coolers into industrial machinery is a critical step toward reducing energy consumption and enhancing overall system efficiency. Their high thermal performance, compact design, and long-lasting durability make them indispensable in applications requiring precise temperature control. By choosing Aluminum Plate-fin Coolers from Wuxi Jinlianshun Aluminum Co., Ltd., businesses can significantly reduce energy costs, improve system reliability, and contribute to more sustainable operations.

English

English русский

русский