Product Knowledge

Plate-Fin Water-Cooled Heat Exchangers: A Reliable Cooling Solution for Chemical Processing

In the world of chemical processing, temperature control is a critical aspect that affects efficiency, safety, and overall performance. Whether in manufacturing, chemical production, or energy generation, maintaining an optimal operating temperature is essential to ensuring that processes run smoothly and efficiently. To achieve this, industries often rely on advanced heat exchange technologies that provide both performance and reliability. One such technology is the Plate-Fin Water-Cooled Heat Exchanger, a robust and efficient solution designed to optimize cooling processes in a variety of industrial applications.

The Importance of Effective Cooling in Chemical Processing

Chemical processing involves various stages where high temperatures are generated, such as during reactions, separations, and distillations. The heat generated during these processes can lead to inefficiencies, potential system failures, or safety hazards if not properly managed. To mitigate these risks, effective cooling systems are essential, and this is where the Plate-Fin Water-Cooled Heat Exchanger excels.

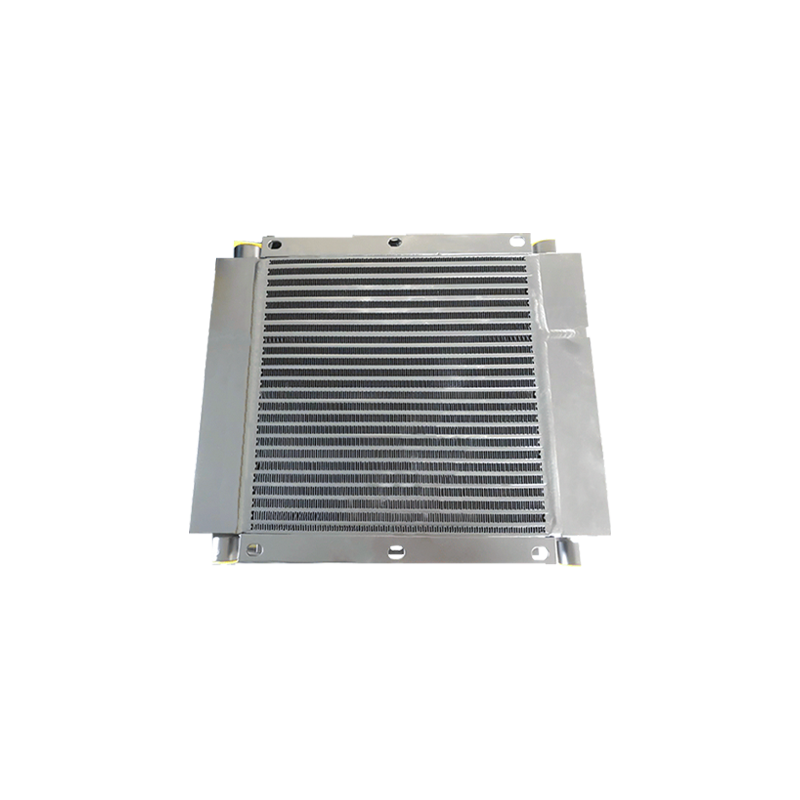

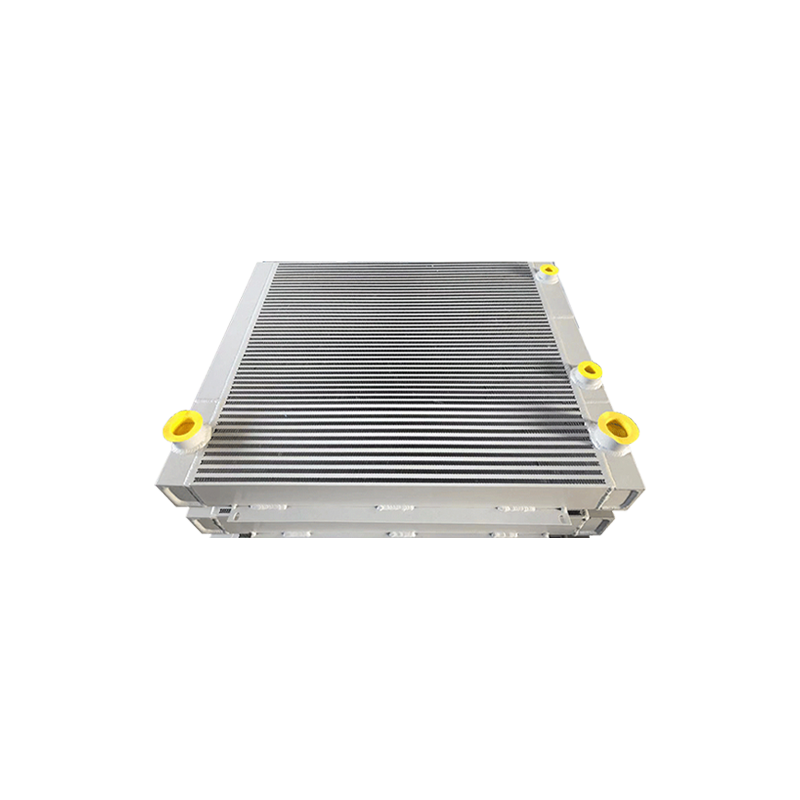

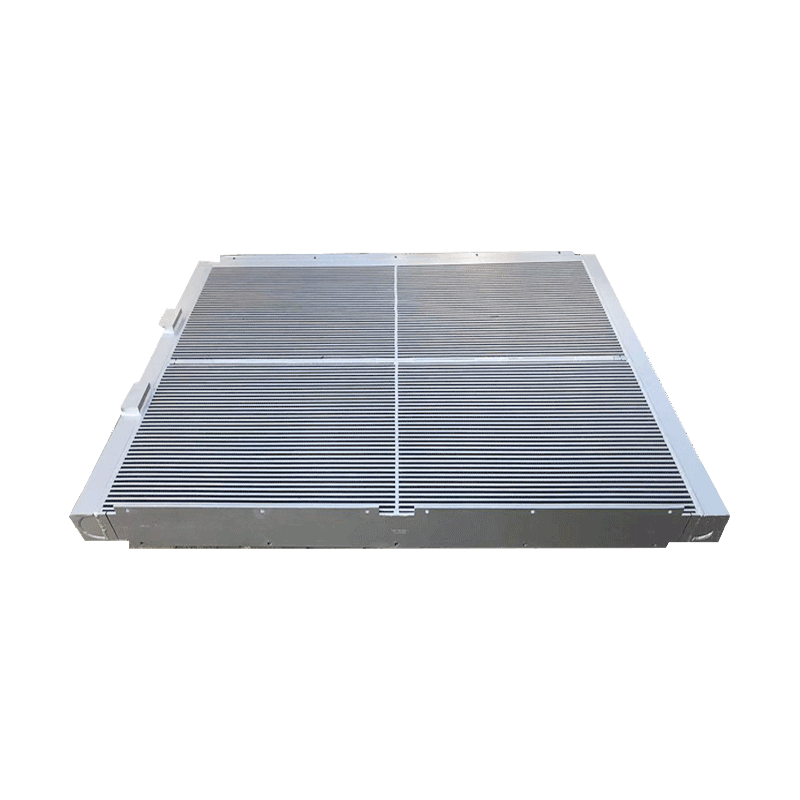

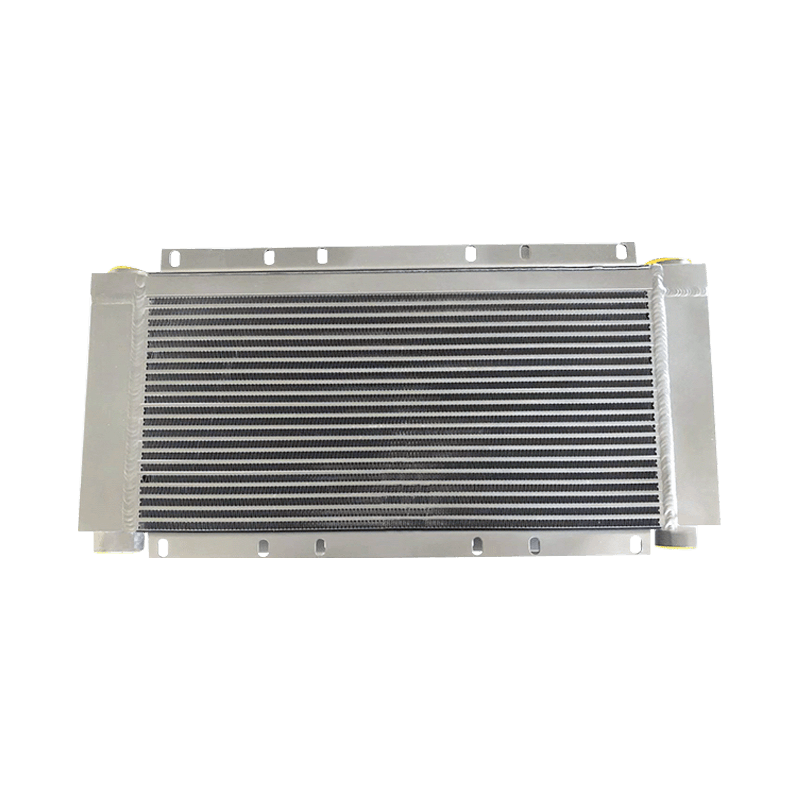

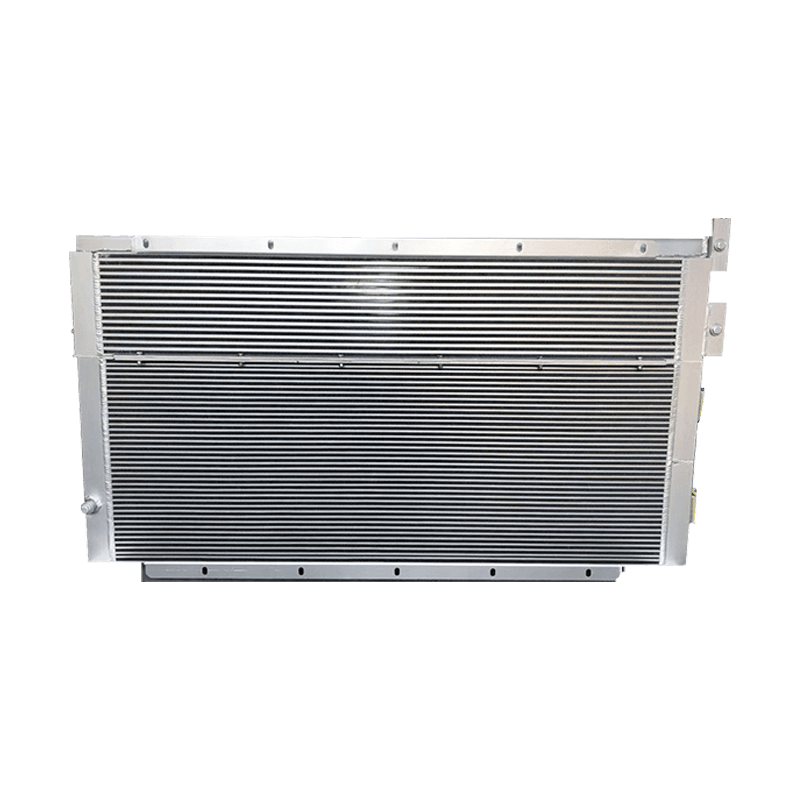

A Plate-Fin Water-Cooled Heat Exchanger is designed to provide superior heat transfer efficiency. It achieves this through its unique construction of multiple layers of plates and fins. This design increases the surface area for heat exchange, which enhances the cooling process. By circulating water through these plates, heat is transferred from the fluid being cooled into the water, which then dissipates the absorbed heat. This system is ideal for maintaining stable temperatures, ensuring that the chemical processes remain within their required thermal conditions for optimal performance.

The Advantages of Plate-Fin Water-Cooled Heat Exchangers in Chemical Processing

One of the key features of Plate-Fin Water-Cooled Heat Exchangers is their high heat transfer efficiency. This is vital in the chemical industry, where maintaining precise temperatures can directly impact product quality and process yields. The larger surface area created by the plates and fins allows for more heat to be transferred in less time, which helps prevent overheating and thermal stress within the system. This efficiency is especially important in large-scale chemical plants where minimizing downtime and maintaining continuous operation is crucial.

Another advantage is their compact size. Unlike traditional cooling systems, which can take up a significant amount of space and weigh a great deal, Plate-Fin Water-Cooled Heat Exchangers are designed to be compact and lightweight. This makes them ideal for industries where space and weight limitations are a concern, such as in tight installations or environments with limited real estate. This small footprint is especially useful in chemical plants where space is often at a premium and every inch counts.

The Plate-Fin Water-Cooled Heat Exchanger also features minimal resistance to fluid flow, which contributes to its energy efficiency. The reduced flow resistance means that less energy is required to circulate the fluids through the system, leading to lower operating costs. In the chemical industry, where energy consumption can be one of the largest operating expenses, this reduction in energy demand translates directly to cost savings.

The Versatility of Plate-Fin Water-Cooled Heat Exchangers

While the Plate-Fin Water-Cooled Heat Exchanger is particularly well-suited for chemical processing, it is a versatile solution that can be applied across a variety of industries. In addition to chemical plants, these heat exchangers are used in power generation, petrochemical processing, HVAC systems, and manufacturing industries. They are also commonly found in industries that require precise temperature control in compressors, refrigeration systems, and even renewable energy applications like wind power generation.

At Wuxi Jinlianshun Aluminum Co., Ltd., the focus on quality and innovation has made their Plate-Fin Water-Cooled Heat Exchangers a popular choice across many sectors. Located in the scenic Taihu Lake region of Wuxi City, the company has a strategic position that benefits from excellent transportation access, allowing for efficient delivery to clients around the world. Specializing in aluminum plate fin heat exchangers, Wuxi Jinlianshun combines cutting-edge technology with superior manufacturing processes to provide high-quality cooling solutions for various industries.

High-Quality Manufacturing for Durability and Performance

The durability and long-term performance of Plate-Fin Water-Cooled Heat Exchangers are paramount for industries that require 24/7 operation under demanding conditions. The exchangers from Wuxi Jinlianshun are made from high-quality aluminum, a material known for its excellent corrosion resistance and lightweight properties. This ensures that the exchangers remain reliable even in harsh chemical environments, where exposure to corrosive substances and extreme temperatures is a concern.

Additionally, Wuxi Jinlianshun offers customizable configurations, allowing companies to tailor the Plate-Fin Water-Cooled Heat Exchanger to their specific cooling needs. Whether it's for a small-scale laboratory setup or a large industrial chemical plant, the company’s flexible design options provide an ideal solution for various applications. Customization options ensure that each system is optimized for maximum performance, energy efficiency, and space-saving capabilities.

The Role of Water Radiators and Water Cooler Heat Exchangers

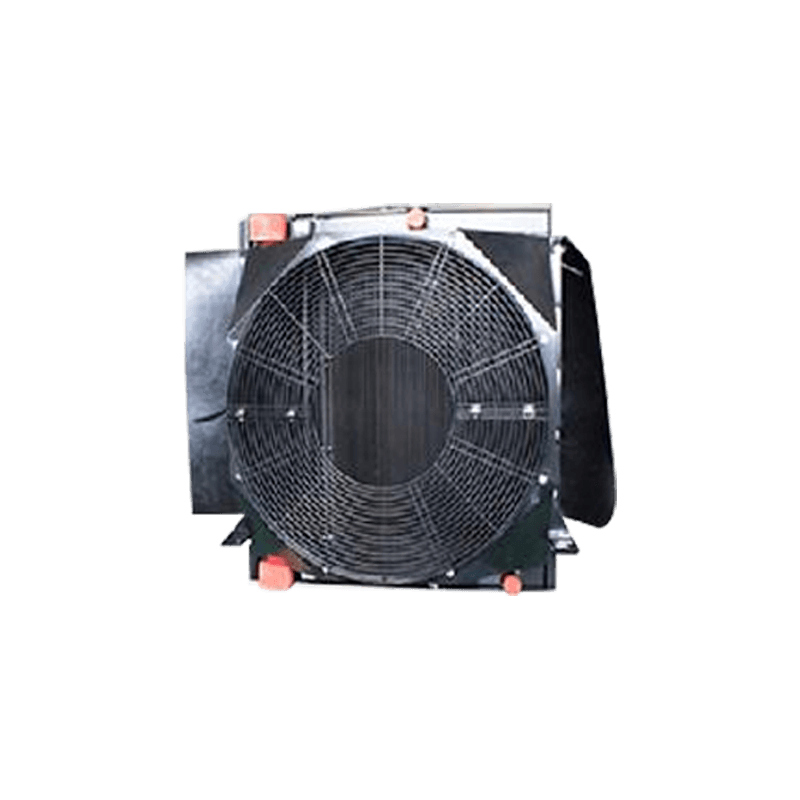

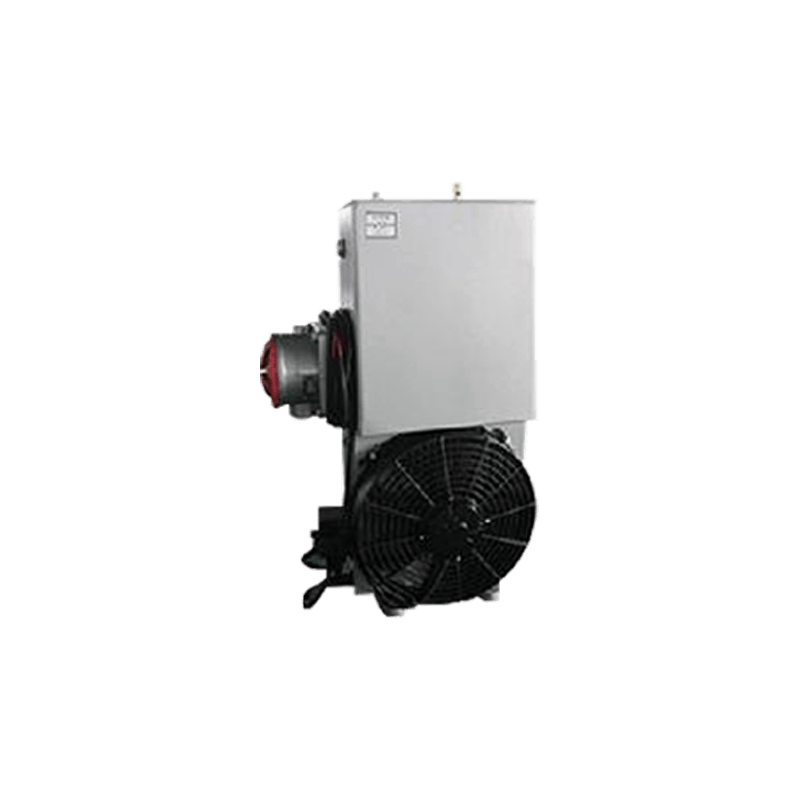

In many chemical processing setups, Plate-Fin Water-Cooled Heat Exchangers are often used in conjunction with Water Radiators and Water Cooler Heat Exchangers. These components work together to create an efficient and reliable cooling system that maintains the correct temperatures for both the process fluids and the water used for cooling.

A Water Radiator serves as an additional heat dissipation mechanism, transferring excess heat from the water circulating through the cooling system. This ensures that the water entering the Plate-Fin Water-Cooled Heat Exchanger remains at the optimal temperature for effective heat exchange. Meanwhile, the Water Cooler Heat Exchanger plays a crucial role in further cooling the water that circulates through the system, ensuring that the temperature is maintained at the desired level, even during periods of high heat generation.

This integrated cooling system ensures that the chemical processing operation runs smoothly, reducing the risk of overheating, maintaining product quality, and improving overall system efficiency. It also helps reduce operational costs by minimizing energy consumption and extending the lifespan of the equipment.

The Plate-Fin Water-Cooled Heat Exchanger is a powerful, energy-efficient, and reliable cooling solution that is critical for maintaining optimal temperature control in chemical processing applications. Its high heat transfer efficiency, compact size, and customizable designs make it an ideal choice for industries where performance, space, and cost savings are key considerations.

Wuxi Jinlianshun Aluminum Co., Ltd. stands at the forefront of manufacturing Plate-Fin Water-Cooled Heat Exchangers, Water Radiators, and Water Cooler Heat Exchangers. With their focus on quality materials, advanced manufacturing techniques, and a commitment to meeting the unique needs of each client, they provide solutions that enhance operational efficiency and long-term performance.

By choosing Wuxi Jinlianshun’s cutting-edge cooling technology, chemical processing plants and other industries can achieve reliable cooling, minimize energy consumption, and ensure the continued success of their operations.

English

English русский

русский